MIXMOBIL MX 2-29

The lifting side panels protect

the operator from the rain and create

storage space for accessories

Control system with a clearly arranged

touchscreen connected to a tablet

with a dispatching programme

System for loading aggregate

while the machine is in operation

without special means of transportation

Description of the Machine

Mixmobil® is a patented, fully automatic production line designed for the production and pumping of cast screed based on an anhydrite and cement binder. Mixmobil is an innovative device that brings high added value to construction work. The machine is capable of continuously producing any amount of cast screed. It is no problem for the one and only Mixmobil to produce 100 m³ of cast screed without a single break in one day. In addition, it has its own stock of materials for laying floors in an ordinary family home.

Mixmobil® offers a range of ground-breaking technology. As well as continuous production, it also enables the production of screed from two aggregate fractions. Two engines are also two things to worry about. Mixmobil® is not fitted with a separate drive unit. The propulsion of the entire machine is ensured by a tractor engine, which has much greater power and meets all emission and noise standards. This solution brings significant savings on weight and space and spares many worries.

Intelligent Control System

Mixmobil® is equipped with a state-of the-art industrial production control system. Microprocessor units are connected to a digital CAN bus with an industrial computer with a 15” TFT LCD touchscreen. The machine also has its own Wi-Fi network with a dispatching programme connected to a mobile inkjet printer. Remote management of the equipment via the internet and an interface for external programmes, such as invoicing software, are a matter of course. Remote radio control allows you to control the pump and other technology (engine shutdown, starting and stopping the pump and adjusting the speed of the pump) and is possible from a distance of up to 200 metres.

Comfort a Practicality

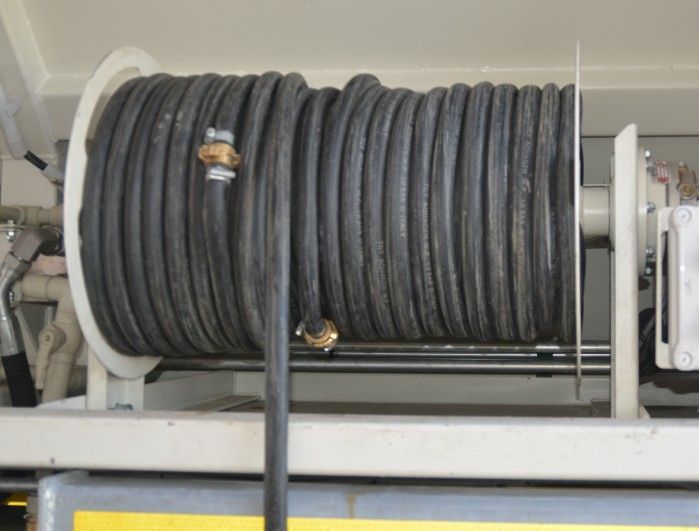

Standard equipment that increases comfort for the operator includes a remote-controlled canvas which covers the sand container, lifting side panels which form a roof above the operator to protect against adverse weather, rotating axles which increase the manoeuvrability of the machine in built-up areas, an easy-to-access hose for pumping mixture and supplying water, generous storage space inside the machine, active dust removal from the mixer and many more sophisticated details.

MIXMOBIL MX 2-29

Easily accessible material hoses

up to 200 metres long

GRUNDFOS hydraulic valves are controlled digitally with the aid of an industrial CAN bus

Water hoses up to 120 metres long

Revolutionary Layout of Technology

Mixmobil® was created by putting great ideas into practice. The uniqueness of its technology is protected by two patents. The layout of the technology itself is patented. The location of the main technology in the central part of the semi-trailer chassis makes it easy to fill the aggregate from the rear of the machine

without the need for further special technology. Aggregate can be topped up by a conventional tipper lorry. The central location of the mixer shortens the transport route of the aggregate to the mixer and ensures excellent distribution of the machine’s weight on individual axles. In particular, this means that there is no

unnecessary strain placed on the rear axle by the technology itself. The high storage capacity of both binder and aggregate provides great variability when discharging the individual ingredients depending on the size of the structure. Binder and aggregate can always be replenished on the building site.

High Performance

It is not only the extraordinary daily production capacity which ranks this machine at the top of its field, but also its high hourly performance. The dynamic weighing system used in the technology is protected by a European patent. The intelligent production control system delivers all components of the cast screed into the mixing equipment simultaneously, rather than one by one. The revolutionary dynamic weighing system shortens the production cycle significantly. The system does not have to wait for the individual ingredients to be weighed as like with conventional competing machines.

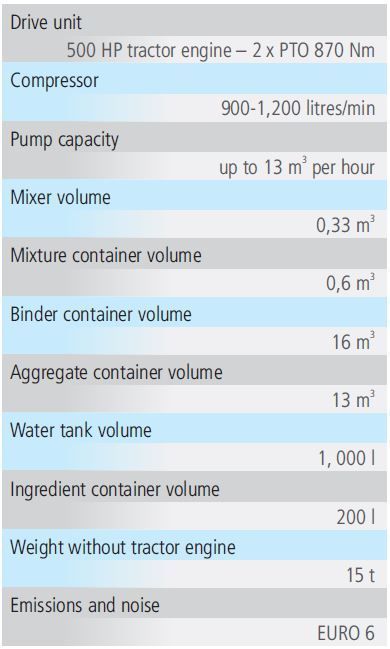

Technical Parameters